Aludecor Systems

Aludecor’s MFR is a ventilated rainscreen system that allows ACP cladding without silicone in the grooves.

Aludecor Systems is a framework and accessories set-up that facilitates rainscreen cladding with silicon-free installations for urban engineering. It is one of the most preferred ACP installation frameworks for ventilated facade suppliers.

Aludecor boosts of one of the most effective and contemporary rainscreen cladding systems - the Male Female Rainscreen System (MFR). The systems have been designed in great detail to adapt to the particular needs of each construction.

Rainscreen claddings are external layers that minimise the force of wind-driven water movement. Ventilated facade systems block the water from entering small breaches on the surface of a building. By the time the water reaches the “true” exterior wall, it loses drive and the ability to permeate the wall. This protective layer literally screens the wall from rains, hence the name.

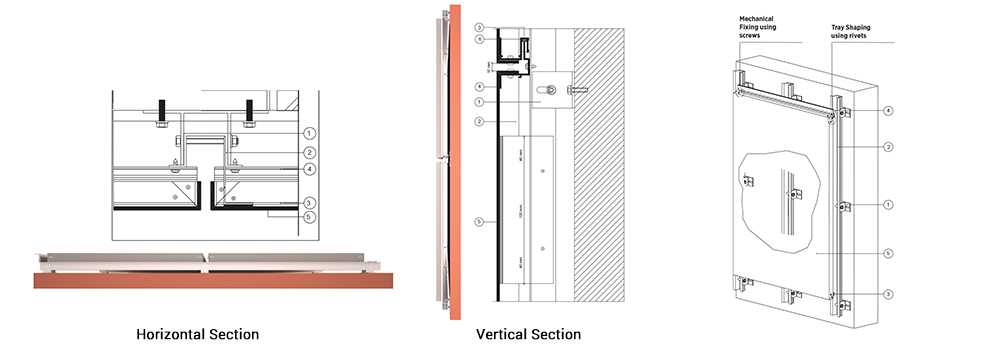

Horizontal, Vertical and close-up cross-sectional diagram of Male-Female Rainscreen system showcasing the principle working scope

| Sl. No | Designation |

|---|---|

| 1 | Double T profile bracket - ALPL/P/210 |

| 2 | Aluminium Profile - ALPL/P/211 |

| 3 | Aluminium Profile - ALPL/P/311 |

| 4 | Aluminium Profile - ALPL/P/312 |

| 5 | Tray made from Aludecor ACP Panel |

| 6 | Neoprene gasket every 500 mm max |

Aludecor Systems give you incredibly flat surfaces. This provides the builder, designer, or architect with the opportunity to develop strong, durable, and aesthetically pleasing façades. A multi-layered rainscreen cladding system can easily outperform its alternative types which adds to its economic viability as well.

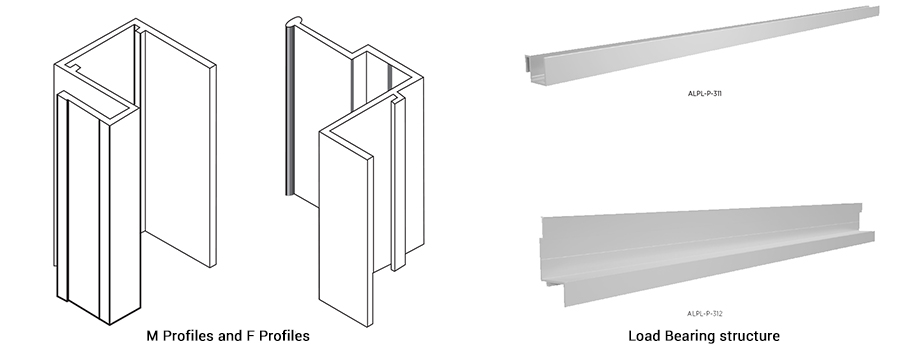

The Aludecor Male Female Rainscreen System (MFR), comprises Male and Female 6063-T6 aluminium alloy profiles and are used for assembling the composite panels on ventilated facades. It is a concealed fixing system that is versatile, easy to assemble, and can be custom-made as per project requirements. There are two profiles in the ventilated facade systems and the shaped trays are fixed on them. This facade system is particularly made in a way that helps to construct ventilated facades for Aludecor’s composite panels with horizontal adjustment.

The substructure is made entirely of 6063 T6 aluminium profiles. It comprises fixings in double T shape of different lengths in order to absorb all irregularities of the façade. In order to avoid vibrations in the panels, the Male and Female profiles have the neoprene protection gasket.

The spacer is fixed to the vertical parameter using special mechanical wedges that are recommended in each case by the fixture suppliers. These double T spacers receive the omega-shaped vertical mullions.

The trays are fixed to the vertical mullions using extruded profiles made from aluminium alloy 6063 T6.

Profiles responsible anchoring the building structure with brackets and special metal accessories

The driving principle behind Aludecor MFR is the back-ventilated facade system.

The space created by the cladding slabs between the wall and the ventilated facade systems creates an insulating layer that improves the thermal efficiency of a building. The system's ability to disperse water vapour through walls, increase soundproofing, reduce maintenance requirements, and allow for the placement of some fixtures outside the structure are all added advantages of Aludecor's cladding systems. The system's adaptability makes it suitable for both new construction and the renovation of existing structures. This system is a great tool for the latter because it can even elevate an existing building's quality. Also, the ventilated facade offers fresh opportunities for creating new options with different terms of composition.

A proper installation of your Rainscreen Cladding System would ensure longevity and superior thermal performance of the facade.

Aludecor Male Female Rainscreen Cladding Installed at Honda, -Assam

Aludecor Male Female Rainscreen Cladding Installed at Honda, -Assam

Aludecor Male Female Rainscreen Cladding Installed at KIA Motors, -Noida

Aludecor Male Female Rainscreen Cladding Installed at KIA Motors, -Noida

Aludecor Male Female Rainscreen Cladding Installed at TATA Hitachi

Aludecor Male Female Rainscreen Cladding Installed at TATA Hitachi

MFR makes the façade strong. This attribute comes from the horizontal fixing style of full-length male and female profiles.

MFR saves time and facilitates the fastest installation thanks to the interlocking process. The panels are supported by extruded aluminium grids.

Using hand routing machine is easy with MFR. It can almost be completely pre-fabricated offsite which saves considerable time and cost.

The maintenance cost incurred is almost zero. The rainscreen cladding systems allows air movement at top and bottom of the elevation ensuring sufficient air movement in the cavity and thus preventing any water, wind, and solar damage.

MFR increases the longevity of the facade by a minimum of 20%. It also comes with a warranty of 12 years (with any Aludecor ACP). Furthermore, if installed through Aludecor Systems then the warranty extends to 15 years for AL45 ACP of Aludecor.

An ACP facade installed through this rainscreen cladding system has grooves of minimum of 3mm width – which can go up to 32mm depending on wind load, panel size, and design that grant the structure a monolithic look. It offers unmatched flatness and leaves zero possibility of undulation.

MFR gives a ventilated facade that aids in insulation. Clubbed with insulation materials, it helps to save energy by at least 30%. An equivalent level of insulation cannot be achieved by the traditional wet seal or rout and return method.

The ventilated facade is an enclosure system from Aludecor that allows an insulating layer and an outer leaf to be placed with the help of supporting structures. The the space between the layers creates a way for natural ventilation of the facade. The benefit of ventilated facade system is that it can be compared to a raincoat as it protects a building from the elements while also fostering a comfortable internal environment. Because of this, the construction method for ventilated facades is frequently referred to as rainscreen cladding.

For construction envelope purposes, rainscreen cladding is now the most effective cladding system. A proper installation of the rainscreen system ensures superior thermal performance of the facade along with longevity.

Sign In

Create New Account